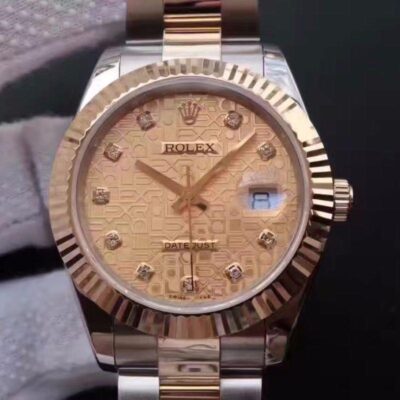

Gold Watches

Gold watch – 1:1 Best Edition Gold Replica Watches,18K gold plating is the process of applying a thin layer of gold to the surface of other metals. The thickness of the 18K gold plating layer can vary, but is usually measured in microns. The process involves electroplating, which uses an electric current to deposit gold ions onto the base metal.

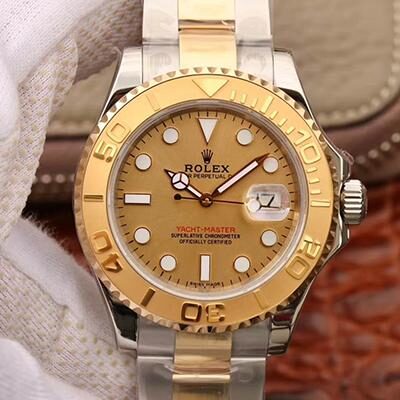

Common base metals used in replica watch production include: 1. Stainless steel: Stainless steel is popular for its durability, corrosion resistance, and ease of processing. It provides a solid foundation for the gold plating process and can perfectly mimic the weight and feel of high-end watches.

2. Brass: Brass is another commonly used base metal. It is relatively inexpensive and easy to process, making it an affordable choice for replica watch production. However, brass is softer than stainless steel and may require additional surface treatment to enhance its durability.

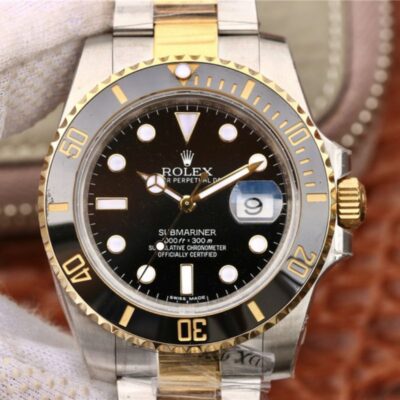

Once the base metal is prepared, the next step is the gold plating process. This is a highly technical process that requires superb craftsmanship and professional skills.

Use solvents and ultrasonic cleaning techniques to clean the metal surface and thoroughly remove any dirt, grease, or fingerprints.

Etch the metal surface to give it a rough texture to enhance the adhesion of the gold plating layer. This is usually done using a chemical solution that reacts with the base metal.

The solution is then used to activate the metal, preparing the surface for electroplating. This step ensures that the metal is conductive and ready to receive gold ions.

Electroplating is the core process of gold plating on base metals. The metal is immersed in an electrolyte solution containing gold ions. An electric current is passed through the solution, causing the gold ions to be deposited on the surface of the base metal. The thickness of the gold layer can be controlled by adjusting the current density and the length of electroplating time.

During the electroplating process, maintaining a constant current and temperature is essential to ensure that the gold layer is uniform and consistent. Any abnormality in the current or solution composition can result in uneven plating, which can affect the appearance and durability of the watch. So this is also the reason why different versions on the market have different prices, whether it is materials, processes, technical levels, etc., there is a big cost gap.